Pleated vs. wound filters for a seawater desalination plant?

Compartir

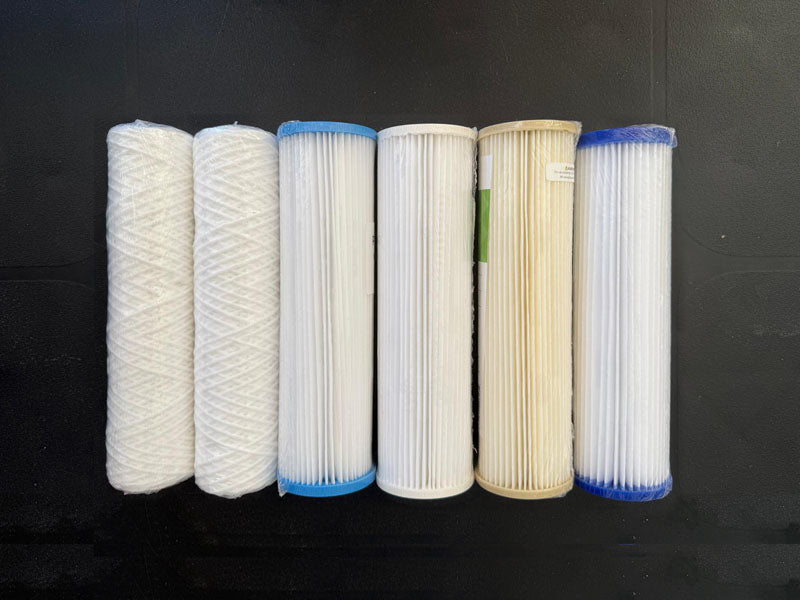

Pleated polyester/cellulose filters or wound filters for a seawater desalination plant?

Selecting the right prefilters is key to ensuring the efficiency and durability of seawater treatment plants. Although wound-wire filters have long been a popular choice, pleated polyester or cellulose filters are gaining ground as a clearly superior alternative in many ways.

Below we explain the reasons:

1. Larger filtration surface:

Pleated filters offer a much larger filtration surface than wound-wire filters, thanks to their accordion-like structure. This larger surface area allows for greater particle retention capacity , resulting in a longer filter life.

2. Improved filtering accuracy:

Pleated filters are available in precise micron sizes, such as 5 or 20 microns, ensuring uniform and predictable filtration . Wire-wound filters, typically made of polypropylene, tend to have a more gradual and less precise filtration rate, which could allow unwanted particles to pass into the water treatment plant.

3. Cost reduction:

Although the initial cost of pleated filters may be slightly higher, their greater particle retention capacity and longer lifespan allow them to be replaced less frequently than a wound-wire filter.

4. Marine Environment Compatibility:

Pleated filters made of polyester are highly resistant to moisture, biological degradation, and prolonged exposure to saltwater, making them ideal for applications in seawater desalination plants. Pleated cellulose can also be a valid option, especially in facilities requiring optimal and regular maintenance.

5. Less waste generation:

Thanks to their greater durability, pleated filters generate less plastic waste over time compared to wound-wire filters, which require more frequent replacements. This contributes to more sustainable practices, an increasingly important factor in water treatment projects.